Soldered Joints involves the method of joining pipe by reduction a filler metal, that includes a low melting stage, in to a joint. While the gel material cools, it ties both items of steel together. This technique is most frequent with copper piping and may be used for water, spend, and vent piping.

The technology behind this technique is very old and has had the oppertunity to tolerate the test of time. Soldered bones are fairly strong and water limited when performed correctly. The learning contour for this technique is normal and it is pretty simple to learn. But, when this approach is utilized on larger length copper piping (3″ and up) there’s a lot of space for human error. The piping has to be washed effectively (using flux) and the person adding has to have enough knowledge applying temperature or torch control. Or even, you run the risk of the combined getting also hot and drawing solder down the bottom of the joint which leaves a hole at the very top and softening the copper itself. In addition, piping materials and filler are expensive. With everyone else being therefore price aware, applying copper may become charge prohibitive.

piping has to be washed effectively (using flux) and the person adding has to have enough knowledge applying temperature or torch control. Or even, you run the risk of the combined getting also hot and drawing solder down the bottom of the joint which leaves a hole at the very top and softening the copper itself. In addition, piping materials and filler are expensive. With everyone else being therefore price aware, applying copper may become charge prohibitive.

Brazing is similar to soldered joints, but it is used largely on water piping (specifically water companies or large length piping), and is much more forgiving. It also uses a gel material with a melting point lower than the bottom material it is being joined to.

Much like soldered joints, this can be a mature technology. The result is that the joint ultimately ends up being stronger than a soldered joint because of the way the gel steel reacts to the steel being brazed. The drawbacks of brazing are similar to that that you simply might discover in soldered joints.

Threaded Fixtures will be employed for repairs or on specialized accessories (flange fittings), but as threaded pipe and fittings relate solely to galvanized water piping, it is a desperate joining option. Galvanized pipe and fittings can be quite difficult to repair. While they start to break up, sediment and corrosion begin to produce within the piping which minimizes the inside size of the piping, usually a significant level of the piping must be changed for repair. The plumbing contractor should have the correct gear available to reduce and bond the pipe. If this equipment is unavailable, the plumbing specialist should have the expertise to evaluate correctly and exchange these dimensions to a wholesaler with the capability to reduce and bond the piping. If possibly of these two points are wrong, the finish impact is just a shutdown of the entire building.

A Fuse Close (Polypropylene piping) is the method of reduction a slim layer of the polypropylene plastic, utilizing a specialized software and hot to a particular temperature, that may then fuse in to one item following about 15 or 20 seconds. Even though this technology has existed because the 60s it’s had an exceptionally tough time increasing popular use. Using a fuse close helps you to save about 20% in substance when comparing to copper. While there is a learning contour to this approach, it is a lot more forgiving than it’s copper counterpart.

This material has almost no contraction or growth (eliminating problems for cold or thawing), it’s no successful conductor of temperature (very little condensation or sweating), there is zero electrolysis (negligible electrical conductivity), and is normally acid tolerant (no hard water worries). There are some services that offer pipe and fixtures which are joined to be natural friendly. Some disadvantages are that, typically, the fixtures are not full port. Such a thing over a 4″ I.D. piping must certanly be a technical joint. Also, due to the lack of stiffness, more pipe hangers (some state dual the amount) must be used. While a large proportion of plumbing technicians have handled that substance sooner or later, the use in the United States is little in comparison to other methods and materials, rendering it less than effective when it comes to labor costs.

A Technical Mutual is any method of joining piping or accessories using combining of a compressed plastic gasket to make sure a water tight close (such as flanged pipe and fixtures or grooved pipe with couplings or fittings). Theoretically, fixes on these purposes are better to perform. The specifications are high since they are high pressure accessories and may be fitted in large diameter pipe and fittings. It will require a reasonably high skill handle to organize and mount that pipe and accompanying fittings.

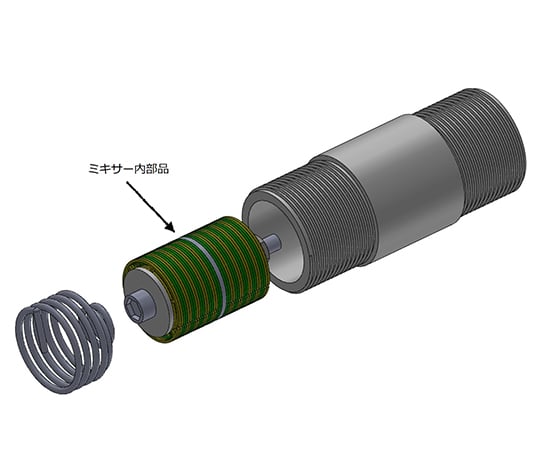

Adding the technical fixtures for スタティックミキサー may be fairly simple, but measuring and grooving of the pipe requires some know-how. To put in or repair flanged pipe , spool pieces, and flanged accessories, the plumbing technician must possess a high ability level. Expenses may be preserved on product, but the repairs and installment can become rigorous and fittings are heavy and expensive.