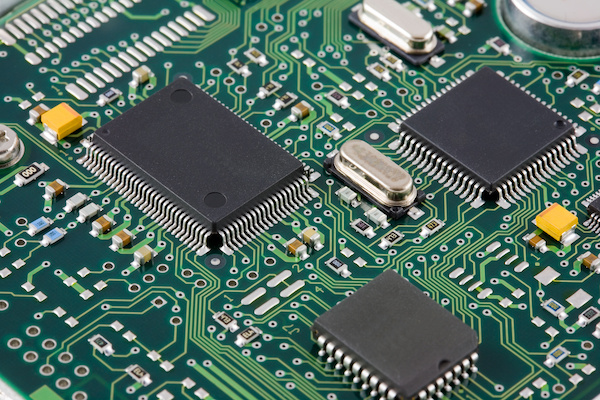

Often, the structure and manufacturing of a printed circuit table (PCB) is since critical as the particular design of the main circuit itself. Manufacturers are increasingly making use of compact, flexible PCBs to assemble and even organize electronic circuits. A PCB may comprise one or more insulating boards on which copper mineral layers and conductive signal traces include been either imprinted or printed. Relying on the complexness of the promenade, printed circuit board manufacturing could commonly involve anywhere coming from an individual layer PCB to eight (or more) layers.

This specific article discusses the particular types of PCBs based on the number regarding layers and the stiffness.

Types of PCBs based on levels

In case you have an extremely basic circuit, the PCB manufacturer can likely recommend the use of a single-sided PCB. Printed circuit board is actually the least complex PCB of all because the entire circuit-comprising the electrical components and even the copper traces-is contained on the single insulating panel.

A double-sided plank holds a rounds that is more intricate than a single-sided board. While the name recommends, both sides with the substrate are used for housing the particular circuitry components. Via hole technology is often utilized whenever manufacturing PCBs which are double-sided or multilayered.

Complex printed signal board manufacturing is usually accomplished via multi-layered PCBs that contain multiple sheets regarding substrate with protecting layers in involving each. Depending upon the complexity involving a circuit, this kind of PCBs could selection from 2 tiers to 4 levels to 8 sheets, going right up to even 40 layers in very sophisticated circuitry.

Forms of PCBs based upon rigidity

Different software need different sorts of PCBs. For instance, a rigid PCB is almost all prevalent and could be found in daily-use consumer electronic digital items such as computers, televisions, cellular phones and thus on. This sort of plank, when bent further than a certain reduce, will crack or perhaps break. The other common type associated with PCBs that are offered by simply a PCB manufacturer is the adaptable PCB. The brake lines in this PCB are assembled on the thin, flexible coating material. This allows the PCB to be curved and curved like desired without inducing damage to the particular circuit or the insulating material. You might see fold PCBs being used in medical gear, flexible heaters, or even even equipment for instance hearing aids.

The particular rigid-flex variety involving PCBs can be a combo of rigid and flexible PCBs. These brake lines are used in aerospace and military applications, where some sort of very dense circuit is required. Rigid-flex PCBs help preserve an important amount involving space, leading to digital products that weigh much less.

Published circuit board producing can be taken out for a new limited number of circuits or with regard to large-volume production. That is essential to be able to choose a PCB manufacturing firm using a proven track report.